Home / Resources / Blog Articles / Precision and Performance: Why Sheet Metal Stamping Parts Drive Modern Manufacturing

Home / Resources / Blog Articles / Precision and Performance: Why Sheet Metal Stamping Parts Drive Modern Manufacturing August 15, 2025

August 15, 2025

In today's fast-paced manufacturing landscape, the demand for high-performance, cost-efficient, and precisely engineered components is more intense than ever. At the heart of many industrial and consumer products lies a fundamental component: sheet metal stamping parts. These parts are ubiquitous across sectors such as automotive, electronics, aerospace, construction, home appliances, and industrial equipment. For procurement professionals, design engineers, and OEMs, understanding the value and application of sheet metal stamping parts is crucial for efficient sourcing, superior design, and competitive advantage. This article Full-Linking provides a deep dive into the key advantages and material selectionfor sheet metal stamping parts.

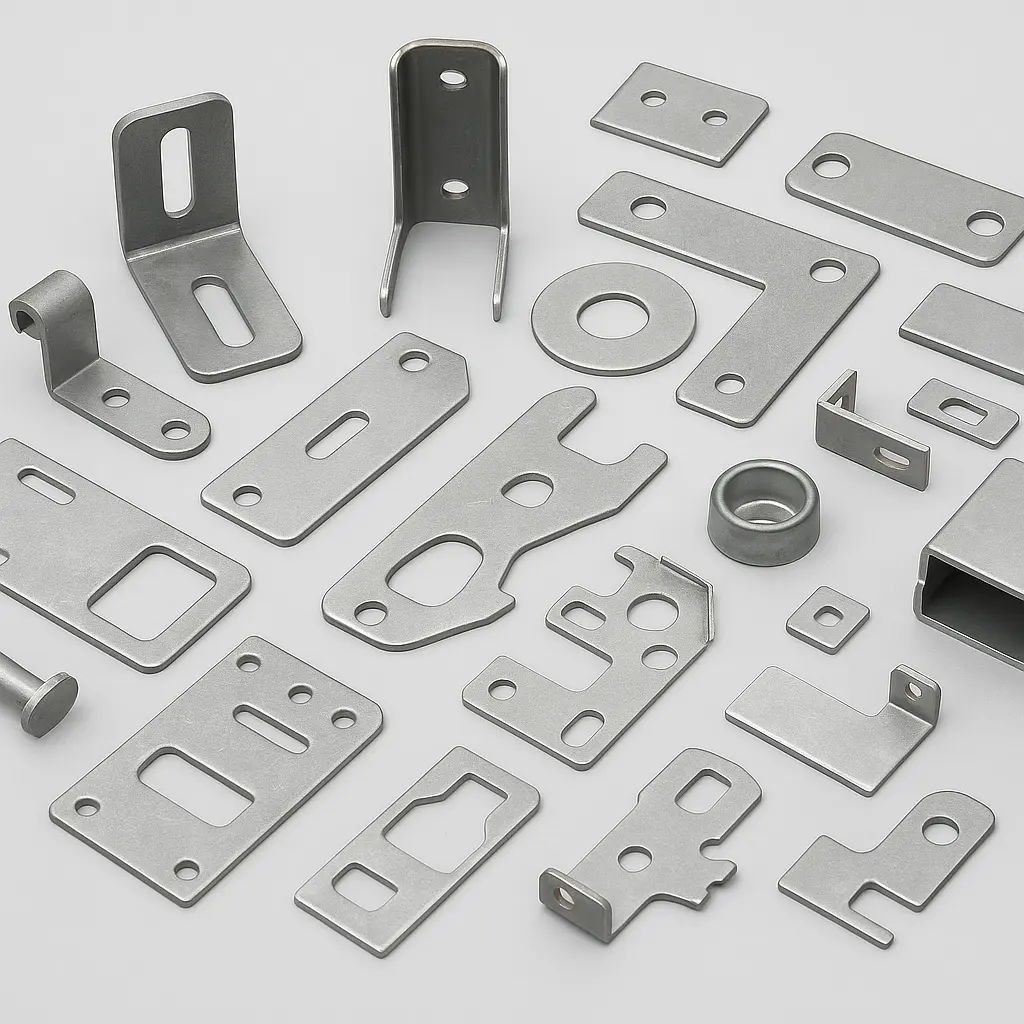

Sheet metal stamping parts are components produced through a cold-forming process that involves shaping flat metal sheets into specific configurations using dies and high-pressure stamping machines. Depending on the complexity of the design, these parts can range from simple washers and brackets to intricate enclosures and housings.

The stamping process may include multiple operations such as:

Blanking: Cutting the raw sheet into predefined shapes.

Punching: Creating holes or cutouts.

Bending: Forming angles or curves.

Embossing: Adding surface features or textures.

Coining: Refining surface finish and edge details.

Deep Drawing: Stretching the metal into deeper, three-dimensional shapes.

What makes sheet metal stamping parts particularly attractive is their repeatability, high-speed production, and cost-efficiency in mass manufacturing—especially when complex geometries and tight tolerances are required.

Choosing the right material is essential to ensure functionality, longevity, and processability. The material not only affects the final part's performance but also influences stamping tool wear, cycle time, and finishing requirements.

Common materials used for sheet metal stamping parts include:

Carbon Steel (Cold Rolled or Hot Rolled): Offers good formability and is cost-effective for general-purpose applications.

Stainless Steel (304, 316, 430, etc.): Provides excellent corrosion resistance for medical, food-grade, and outdoor products.

Aluminum Alloys (1050, 5052, 6061, etc.): Lightweight with good strength-to-weight ratio and corrosion resistance.

Copper and Brass: Ideal for electrical contacts, decorative elements, and precision instruments.

High-Strength Low-Alloy (HSLA) Steel: Used where additional strength is required without increasing part thickness.

The chosen material must align with the product's mechanical, thermal, and environmental requirements. For example, sheet metal stamping parts for an automotive chassis must meet both high strength and fatigue resistance standards, while parts for consumer electronics may prioritize conductivity and cosmetic appearance.

Sheet metal stamping parts are highly valued in various manufacturing industries for their efficiency, precision, and strength. The process of stamping, which involves using custom dies and high-tonnage presses to shape sheet metal, offers a wide range of advantages that make it indispensable for both small and large-scale production.

One of the most significant benefits of sheet metal stamping parts is the exceptional dimensional accuracy they provide. Modern stamping presses, when combined with CNC-controlled tooling and precision dies, produce components that consistently meet tight tolerances. This level of precision is crucial in industries like automotive, aerospace, and electronics, where even the smallest deviation in part dimensions can lead to performance failures or safety risks. Sheet metal stamping parts are designed to ensure that components fit together seamlessly, maintaining the integrity of the final product. This precision helps reduce the need for secondary operations, saving both time and cost during production.

Sheet metal stamping parts are ideal for high-volume manufacturing due to their scalability. Once the die is designed and created, sheet metal stamping parts can be produced in large quantities at a rapid pace with minimal cycle times. Whether producing hundreds, thousands, or even millions of parts, the process remains consistent and efficient, making it the perfect solution for mass production. The repeatability of the stamping process ensures that each part is virtually identical, reducing the risk of variability and improving overall quality control. This scalability makes sheet metal stamping parts a popular choice for industries that require large quantities of components without sacrificing quality or speed.

Compared to other manufacturing methods like machining or casting, sheet metal stamping parts offer superior cost efficiency. The stamping process involves less material waste and requires fewer labor hours per part, especially when compared to traditional machining methods that often involve removing material from a solid block. This reduction in material waste translates into lower costs for raw materials, making sheet metal stamping parts an attractive solution for cost-sensitive projects. Additionally, because the stamping process is automated and requires minimal manual intervention, labor costs are also reduced. As a result, sheet metal stamping parts are often the preferred choice for projects with high repeatability and tight cost constraints.

Sheet metal stamping parts benefit from the original grain structure of the sheet material, which can enhance the strength and durability of the finished part. During the stamping process, the metal is often subjected to work hardening, a phenomenon that increases the strength of the material as it is formed. This means that sheet metal stamping parts are typically stronger and more resistant to wear and tear than parts produced through subtractive processes, such as machining. The preservation of the material's structural integrity makes sheet metal stamping parts ideal for applications where durability and resistance to mechanical stress are critical, such as in automotive frames, aerospace components, and heavy machinery.

Another advantage of sheet metal stamping parts is the flexibility in surface finishing options. After the stamping process, the parts can be post-processed with various surface treatments to meet specific aesthetic, functional, or protective requirements. Options like powder coating, anodizing, galvanizing, and polishing allow manufacturers to provide sheet metal stamping parts with superior resistance to corrosion, abrasion, and wear. Additionally, surface treatments can improve the appearance of the parts, making them more suitable for consumer-facing products. Whether the goal is to enhance the part's strength, appearance, or corrosion resistance, sheet metal stamping parts can be customized with different finishes to meet the needs of various industries.

Sheet metal stamping parts form the backbone of countless products that drive modern life. Their ability to deliver precision, strength, speed, and cost-efficiency makes them essential to competitive manufacturing operations. Whether you're sourcing a small bracket for an electronics enclosure or a load-bearing chassis component, the right stamping partner and material choice can dramatically affect your product's performance, budget, and lead time.