Home / Resources / Blog Articles / Revolutionizing Manufacturing: How Online Injection Molding Services are Streamlining Product Development

Home / Resources / Blog Articles / Revolutionizing Manufacturing: How Online Injection Molding Services are Streamlining Product Development June 05, 2025

June 05, 2025

In the fast-paced world of product development, speed, precision, and cost-efficiency are critical factors that dictate success. As consumer expectations rise and time-to-market windows shrink, businesses are increasingly turning to digital solutions that accelerate prototyping and production without compromising quality. Among the most transformative innovations is the rise of online injection molding services. These platforms enable engineers, designers, and entrepreneurs to upload CAD files, receive instant quotes, and initiate the molding process within hours—all from a web browser. Online injection molding service has redefined how companies approach part manufacturing, making it more accessible, scalable, and responsive. Whether you are an established OEM, a startup launching a new product, or a contract manufacturer seeking agility, Full-Linking offers a comprehensive solution that combines the benefits of traditional molding with the flexibility of digital infrastructure.

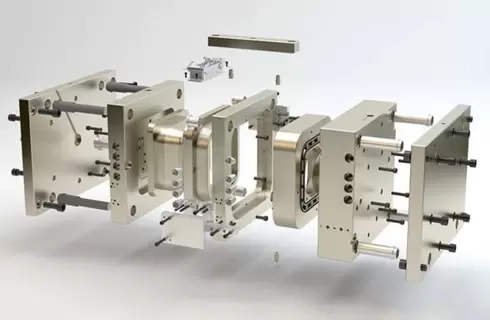

An online injection molding service is a digital manufacturing solution that provides end-to-end injection molding capabilities via an internet-based platform. These services allow users to upload 3D CAD models directly to a web portal, where the software analyzes the design, generates quotes instantly, and provides feedback on manufacturability. Once approved, the parts are manufactured using automated or semi-automated processes, including CNC-machined molds, thermoplastic injection, and quality inspection.

This model eliminates the need for manual communication and extended back-and-forth cycles with suppliers. It brings high-speed responsiveness and accuracy into the traditional injection molding process, making it ideal for rapid prototyping, low- to mid-volume production, and even high-volume runs. Online injection molding services integrate cloud computing, data analysis, and advanced manufacturing technologies to deliver faster, more transparent, and scalable production capabilities.

One of the standout features of an online injection molding service is the ability to receive immediate pricing and design-for-manufacturability (DFM) feedback. Traditional molding workflows often involve lengthy communication cycles, quoting delays, and manual design reviews. Online platforms leverage automated tools and AI algorithms to analyze uploaded CAD models in real time, flagging potential issues such as undercuts, wall thickness anomalies, or draft angle deficiencies. This real-time feedback empowers engineers to iterate quickly and efficiently. By optimizing part geometry before tooling begins, companies can minimize costly revisions, shorten lead times, and improve overall manufacturability. Engineers can run multiple simulations within the platform, adjusting critical features such as ribbing, bosses, and snap-fits to meet both functional and aesthetic goals. The end result is a streamlined workflow that promotes better part quality and faster design approval.

Traditional injection molding can take weeks or even months to move from concept to molded part due to tooling complexity and vendor coordination. Online injection molding services streamline this process by utilizing rapid tooling technologies such as aluminum molds, modular tooling inserts, and CNC-machined components. These methods drastically reduce setup times while maintaining high precision and repeatability. In many cases, parts can be produced and shipped within 7 to 15 business days, which is particularly advantageous for low-volume production, pilot runs, and prototyping. This speed enables agile development cycles, allowing teams to test market viability and make design adjustments with minimal delay. Additionally, many services support quick mold revisions and part iterations, making it easy to transition from prototype to final product within a single platform.

While often associated with prototyping, online injection molding services are increasingly capable of supporting full-scale production. Advanced platforms offer a range of molding options, from short-run batches to high-volume manufacturing, all within a unified service architecture. This scalability allows companies to grow seamlessly from prototype to commercial product without switching vendors or retooling processes. Additionally, clients can select from a wide array of thermoplastics, additives, finishes, and tolerances to meet specific performance and compliance requirements. The ability to fine-tune these variables ensures that parts not only look the part but perform under real-world conditions. Many providers also offer dedicated account managers and project engineers to support scaling operations and ensure consistent quality over time.

Online injection molding services are more than a convenience; they are a paradigm shift in how modern manufacturing is executed. By digitizing the entire workflow—from quote to final part—these platforms eliminate bottlenecks, reduce costs, and empower teams to innovate at unprecedented speeds. Whether you're launching a new consumer device, iterating a medical prototype, or managing an automotive part line, an online injection molding service can be a powerful ally in your product development journey. As digital manufacturing continues to evolve, embracing these services is no longer optional—it's essential for staying competitive in today's dynamic market.